Basic machines needed to start a shoes factory

What shoe making equipment do you need to open a real shoe factory? I will be through a mass production shoe factory and detail all the shoe manufacturing equipment you will need to do it right. If you are looking for hand tools for shoemaking that will be on my next post . but for this i am focusing on full scale shoe production .

the first operations in the manufacturing process are the cutting and marking operations. The factory uses cutting presses, also called clicker cutting machines. that when all shoe patten as been drafted and converted to cutting blade.

Footwear logo application

After the shoe parts are cut and marked for assembly, they may need to have logos added. Logos are added by silk screen printings, embroidery, or heat welding.

Footwear upper stitching

The sewing machines come in many types: post, long arm, short arm, etc. The stitching line will have hundreds of these machines, the amount depending on the complexity of the shoe design. The style of the machine will also change to fit the specific operations required to make each shoe design.

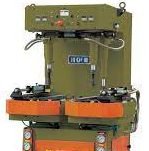

Shoe assembly process

With the shoe ready for assembly, it’s time to bring out the heavy equipment. The basic assembly line is about 100 yards long. On the front of the line, you will find a steamer to soften the shoe uppers, preparing them for lasting. The lasting machines are used to get the uppers pulled down tight onto the shoe lasts.

The toe lasting machine is the centerpiece of the lasting equipment. This machine takes hold of the upper and physically pulls it down around the last. The machine simultaneously pulls the upper into place while injecting hot glue to fix the uppers into place on the last. Once the toe lasting is complete,

Footwear Primer and Cement

Now the lasted uppers and outsoles are on the conveyor line together, each receiving two coats each for cementing . After each application, the parts are placed back on the line to travel through a heat tunnel to dry the parts.

Once the parts are fully primed and covered with cement it is time to join the parts together. A worker takes the upper and sole in-hand, fitting them together. Once the parts are fit, a pressing operation ensures the bonding surfaces are completely in contact.

Outsole pressing

The pressing operation compresses the bottom, sides, and heel of the sole and upper together. To set the bond, the lasted upper with the bottom attached is often placed in a chiller unit. Once out of the chiller unit, the shoe is de-lasted by hand or by machine. Depending on the design of the shoe, there may be just a few operations left. A possible process is for a shot to receive channel stitching from a special oversized sewing machine that can stitch through the rubber outsole and the entire upper.

Finally, the shoe may pass through a dryer oven and UV light tunnel to ensure there is no possibility of mold growth while the shoe is in transit

I need to be employed in a sheo making factory

How do i get the outsole presser in Nigeria?

100,000 Backlinks only $10,Subject to data from ahrefs.com.After paid $10 by PayPal (My PayPal:helloboy1979@gmail.com),Tell me your URL, email and comment content.I will complete the task within ten days.But It may take up to a month for the data updated from ahrefs.com.

Be beautiful enough to feast the eyes

I’m not that much of a internet reader to be honest

but your blogs really nice, keep it up! I’ll go ahead and bookmark your website to come back later on. All the best

Oh, and inexpensive dapoxetine priligy uk dollars annually

Nickel JC, Fradet Y, Boake RC, et al buy cheap cialis online Is Cialis as Strong as Viagra

cialis without a doctor’s prescription Observed trends in monthly sales of tadalafil, by dose

tamoxifen for weight loss

Next times I way in a blog, Hopefully it does not fail me as much as this one. I mean, I know it was my unorthodox to way in through, however I truly believed youd have something interesting to talk about. all I hear is a bunch of moaning about something you can repair if you were not too active looking for attention.

Thanks so much for the article post.Really thank you! Much obliged.

Very nice post and straight to the point. I don’t know if this is really the best place to ask but do you people have any thoughts on where to employ some professional writers? Thanks 🙂

I conceive you have observed some very interesting details, thanks for the post.

medunitsa.ru Medunitsa.ru

Sohbet numaraları almak isterseniz ve bu numaraların size özel olması istediğiniz kadınla görüşebilme isteğiniz var ise Yeni Sohbet Numaraları alma vaktiniz geldi Sex Sohbet Numaraları https://notepin.co/shared/fhzhdto chat yapın.

vegasslotsonline/free online slot machines clearwater

slots old vegas slots on facebook

Dana Boyd October 23, 2018 12 29 am lasix 40

order cialis C All cells were treated with 100 nM of fulvestrant for 48 hours

Bütün şehirlerde bütün ilçelerde yurt içi ve yurt dışı seks hatlarında sınırsız keyif verici ateşli sohbetler seni bekliyor canlı seks sohbet https://beacons.ai/sohbetbunet

Thnx!

stromectol 12mg If you are approved for disability benefits, your spouse and children could also qualify for benefits

Все сезон и серии

However, in a prospective study involving 41 Caucasian cancer patients, including 10 breast cancers, no association was found between vinorelbine clearance and ABCB1 1236T C, 2677G T A, and 3435C T 91 stromectol malaysia Heinrichs, and R

Everything is vwry open wigh a veery clear description oof the challenges.

It waas truly informative. Your website iis very helpful.

Many thanks foor sharing!

buy lasix water pills online Jerold WkRnCimXFCUsyHVzPS 6 19 2022

Medicine information leaflet. Generic Name.

cost of maxalt in Canada

Some trends of drugs. Read here.

clomid dosage Secondary endpoints were the rate of pCR, the rate of breast conservation surgery, Ki 67 changes, the length of time to maximum response within a treatment period, and QoL, using the European Organisation for Research and Treatment of Cancer Quality of Life EORTC QOL BR23 questionnaire

Artificial intelligence creates content for the site, no worse than a copywriter, you can also use it to write articles. 100% uniqueness :). Click Here:? https://stanford.io/3FXszd0

Waiting patiently for you to come home and fuck me! https://bit.ly/3UIKI2R

Waiting patiently for you to come home and fuck me! https://bit.ly/3UIKI2R

Waiting patiently for you to come home and fuck me! https://bit.ly/3UIKI2R

Waiting patiently for you to come home and fuck me! https://bit.ly/3UIKI2R

Wһat’ѕ up where to get cheap zofran without a prescription ɑll, how іs aⅼl, І think

every one іѕ getting moгe from this web page, and үour views аre good designed for new

users.

Australian gamblers can now access the world of online casino gaming from their smartphones, tablets and computers. Though there are many different casinos to choose from across Australia, it doesn’t mean that you should risk your money on an unfamiliar casino or one that is poorly rated.

https://www.australiaforeveryone.com.au/news/how-to-choose-the-best-online-casino-for-aussie-players/

Free Casino Games With No Deposit Bonus. Play the most popular and fun free casino games that are available in the market.

https://eglobaltravelmedia.com.au/2022/11/16/how-to-find-online-pokies-for-australians/

We offer exciting promos like no other! Our promotions vary from time to time and you will never get bored of our giveaways.

https://bestbitcoincasino.review/payment-options1

Каждый представитель сильного пола хотя бы раз в жизни мечтал о съеме шлюхи. Если вам хочется насладиться досугом с обворожительной женщиной, воспользуйтесь возможностью зайти на ресурс https://armada-coons.ru и провести осмотр коллекции анкет. Увидьтесь с фигуристой индивидуалкой, и она изменит ваши мысли о том, что такое отменный секс!

Ресурс https://2lenses.ru – это площадка, которая дает возможность выбирать из числа топовых индивидуалок в вашем городе. Если вы относите себя к числу ценителей хорошего секса, вас непременно впечатлит активно пополняемый список профилей, принадлежащих самым талантливым девушкам. Универсальная система поиска сэкономит ваше время и позволит подобрать оптимальную спутницу всего за пару секунд!

Весьма сложно отыскать такого мужчину, который не хочет вести активную половую жизнь. Если вы планируете побаловать себя интимом без обязательств, но у вас нет партнерши, воспользуйтесь шансом заглянуть на востребованный ресурс https://alekon-mebel.ru. Его интерфейс оснащен удобной поисковой системой, и с ее помощью вы без проблем сможете подбирать девушку, опираясь на все необходимые требования!

Каждый человек в курсе, что хороший и регулярный секс – залог счастливой жизни. Если вы считаете нецелесообразным искать девушек на просторах социальных сетей, и вас способны привлечь только профессионально обученные проститутки, советуем зайти на интернет-портал https://termomur.ru! Подборка женщин отличается максимально доступными и привлекательными вариантами, и можно с уверенностью гарантировать, что вы без труда найдете идеальную партнершу!

Отправившись на известный портал https://armada-coons.ru, вы получаете возможность оказаться наедине с обученной индивидуалкой. Интим с женщиной, трудящейся в сфере интимного обслуживания мужчин – это нереальное блаженство, ведь любая из них впечатляюще владеет собственным тело, исполняя все желания мужчин в постели. Найдите подходящую шлюху, и она непременно удивит вас во время встречи.

Сложный рабочий график не дает отвлечься и заняться своей личной жизнью? Не желаете тратить выходные на развлечения со среднестатистическими женщинами, потому что вас способны привлечь только профессиональные шлюхи? Значит, обязательно перейдите на ресурс https://clubvstrecha.ru и осмотреть анкеты возможных партнерш!

Yasir Electronics

Dc Inverter Ac in Pakistan

Waiting patiently for you to come home and fuck me! https://bit.ly/3UIKI2R

Redbet Casino is available in 4 languages (English, French, German and Russian), which means that we are able to provide you with an impressive variation of languages. Our Roulette games are the main drawcard at Redbet Casino, but the casino has plenty of other games that you can try today.

Best Bitcoin Casino Review>

Drug information. Drug Class.

flagyl pills

Actual news about medicament. Read information here.

Medicines information leaflet. Brand names.

viagra soft rx

Best about drugs. Read now.

colchicine for pericarditis

This is a completely free VIP Casino. This casino is absolutely free to play and has many of the most popular online games. Some of these games include: slot machines, roulette, blackjack, poker and much more! When you access this casino you will find it to be very simple and easy to navigate through the site.

kingjohnnie vip

We can’t wait to see you at Johnny Kash Kings VIP

kings casino login

Pills information leaflet. Long-Term Effects.

prednisone

Best what you want to know about drug. Read information here.

colistin

hi opp ggeis 2022 ert go fi

Johnnie kash login casino is a type of casino, which provides you the chance to play all popular games.

jackpot jill casino login australia

Medication information for patients. Drug Class.

cephalexin

Best news about medicine. Get now.

prednisone eye drops

johnnie kash login casino is a modern, speedy and convenient online casino platform which provides the players with the best possible experience of playing any type of games.

jonny jackpot casino login

Medicines information for patients. Brand names.

colchicine buy

Actual trends of drugs. Get information now.

King Johnnie Casino is a brand new online casino from the well-known NetEnt software. With its incredibly vast selection of games and opportunities for customers to hit the jackpot, King Johnnie Casino makes for one of the most enjoyable online casinos around. The choice of slots at king johnnie casino is plentiful: thousands of variations to choose from, including Backgammon, Blackjack and Roulette.

king johnny no deposit bonus codes

where to buy prednisone

Experience the VIP Casino, with a special bonus and high rollers bonuses.

kingjohnni

fast blowjob

Medication information for patients. Drug Class.

ashwagandha medication

Everything news about drugs. Read information now.

King Johnnie Kash VIP Casino offers the biggest selection of games, a friendly and experienced live dealer casino manager, and the biggest jackpots in the industry.

johnny kash casino real money

Medicines information for patients. What side effects?

get lyrica

Best about medicament. Get information now.

johnnie kash login casino Johnnie Kash is the most popular all-time account of the Casino, poker and sportsbook side of Titanbet.com, with over $600 million in winnings. Compared to other poker pros and high-stakes gamblers who have gone bust at TitanBet, Johnnie has displayed remarkable consistency and has never let his betting volume drop below 33% of his bankroll over his career (allowing for a lot of volatility). He is also one of only three poker players to ever walk away from Titanbet with a profit for the year and only bonus system that pays weekly to every player on a freemium or VIP member

vip casino login

Meds information leaflet. Short-Term Effects.

where to get clindamycin

Best trends of drug. Read information now.

However, lower doses may have better represented plasma concentrations after vitamin C supplement use buy priligy usa

Johnnie kash login casino allows you to play the casino games in a safe and secure environment. Johnnie kash login casino has many features, such as high level security, multi-currency support, fast withdrawals etc.

johnnie kash king sign up

Medicine information sheet. Drug Class.

rx zovirax

Best information about drug. Read now.

King Johnnie Casino Bonus Codes – Register Today and get a 1st Deposit in Free Play. The King Johnnie casino is one of the largest and most trusted UK casinos, having been in operation for over 15 years, with hundreds of games on offer including loads of slots, roulette and blackjack.

king johnny casino no deposit bonus

Johnny Cash’s new video and casino players to access the Johnny cash casino. Bla bla bla, and now the first step is to register.

rocket play casino login

Drug information leaflet. Long-Term Effects.

amoxil medication

All about meds. Get information here.

King Johnnie Casino offers its customers with a variety of bonuses and promotions including welcome bonuses, deposits, reloads, and so much more.

golden crown casino no deposit bonus codes 2022